Sanitary sewer lift stations are critical to a municipality’s infrastructure to maintain a reliable collection system. There are multiple components for lift stations that should be reviewed and assessed intermittently to make sure a station operates efficiently and effectively with redundant and back-up systems. Assessments should include condition, code, and capacity considerations.

Lift station systems include electrical and control components, mechanicals such as pumps, valves and piping, building systems, structural systems such as the wet well and valve manhole (if applicable), and site considerations. Wet well operating volume and firm capacity (the capacity of a station without the largest pump in service) are also critical components. A brief overview of these items is discussed below.

Electrical and Controls

Things to check in this area include the condition of the contacts in the pump control panel, conduit seal-offs coming into the control panel, not having cable strain in the wet well for submersible stations, and that the pump alternator is functioning correctly. Telemetry components should also be considered. Having more equipment monitoring tags can save operators from making unnecessary trips to the site to address nuisance alarms. An example of this is having specific generator condition alarms instead of a general alarm that requires a site trip for investigation.

Mechanical

Critical items to check for mechanicals include if the pump makes abnormal noise or vibration while operating, whether the plug and check valves seal tight, and plumbing and HVAC components inside a building and the standby generator if applicable. Often at a lift station, the generator has very low run-time hours. The ability to get replacement parts for a generator governs the service life. The generator's typical age where it is very hard to get replacement parts is 30 to 35 years.

Building

Building at lift stations house pump controls, telemetry equipment, other electrical components, and standby generators should be inspected as well. Building components that are important to access include the condition of the roof, wall system, louvers and damplers, and door/door hardware.

Structural

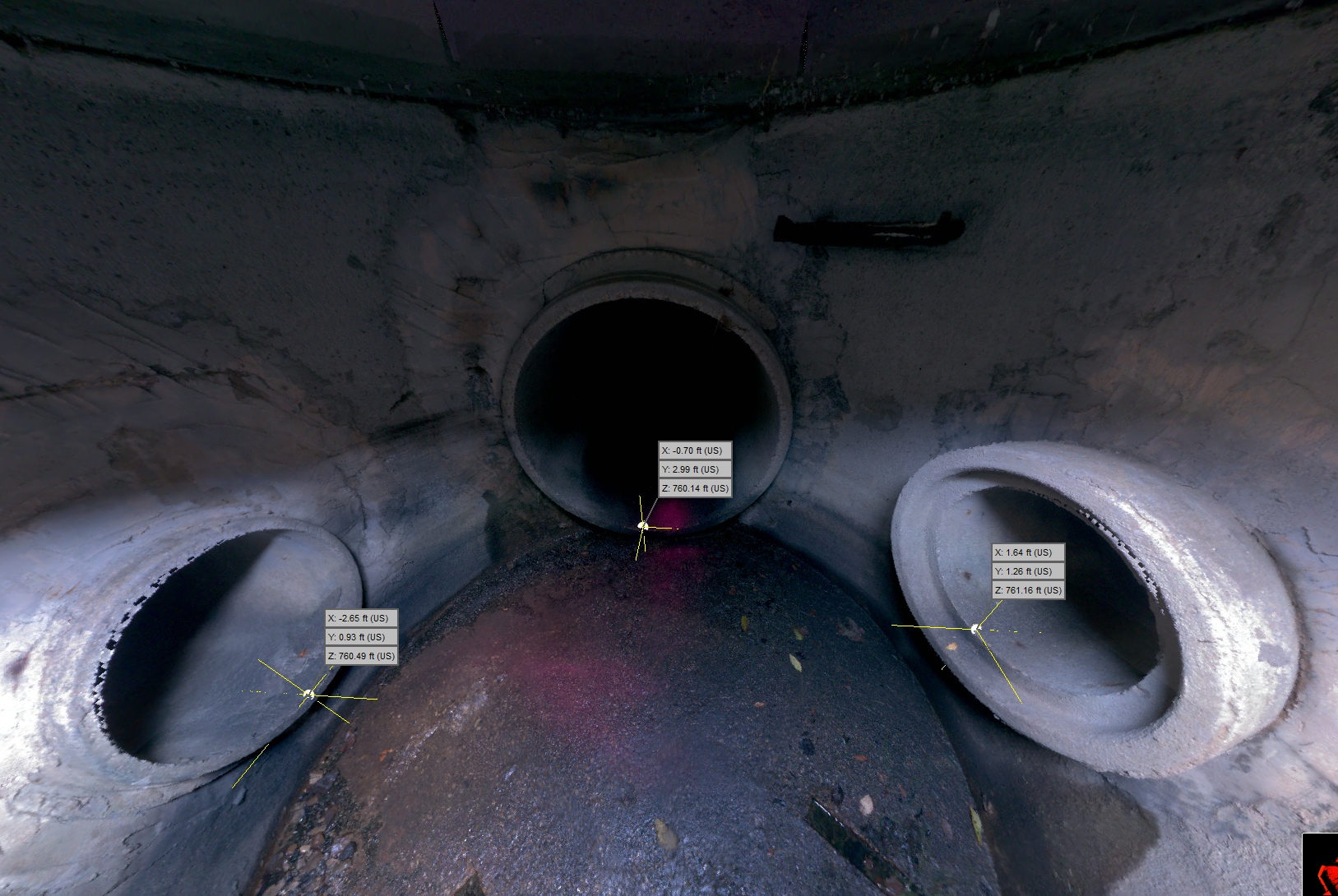

The condition of the wet well and valve manhole should be checked for corrosion and groundwater leakage. The typical life for a concrete structure is 75 to 100 years old.

Wet Well Operating Volume

Also, as a community grows and develops, the required pumping rate increases. For stations without pump driven by a variable frequency drive, the required wet well operating volume which is the “pump on” level to the “pump off level”, increases to maintain the code -required minimum pump cycle time of 5 minutes. Cycle times even longer than 5 minutes are advantageous to extend the life of pump motors. Sometimes a new, deeper, wet well structure is required for the necessary wet well volume.

Firm Capacity

It is code-required that there needs to be sufficient pumping capacity with the largest pump out of service. To analyze this, it is useful to review pump operating times during and after significant (greater than 2-inches) rainfall and significant snowmelt events. The total runtimes during these times for a duplex station should be less than 24 hours per day. For a triplex station, the total runtime should be less than 48 hours per day. If the runtimes are greater, this indicates that the station firm capacity is not great enough.

Site

Site conditions include security (wet well access door padlocks, fences, door switches and locks for a building), lighting for emergency operations at night, drainage away from the wet well and building, and pavement condition. Space should also be available for utility trucks for routine operation to allow for turning movements and pump removal.

R/M Can Help!

R/M is ready to help your community with lift station assessments taking into account all these factors and more.

about the author

dave w. arnott, p.e.

Team leader / senior project manager

Dave has extensive experience in the planning, design, and construction project management of wastewater treatment facility renovation and upgrade projects. Areas of expertise include treatment processes, hydraulics, mechanical equipment, and wastewater disinfection. He also has experience in sanitary and water pumping station design and sanitary sewer wet weather facilities.